How to Tell When Your Brake Discs Need to Be Replaced

The braking system is one of the most essential safety mechanisms in any vehicle. Its proper operation directly affects a car’s ability to stop in time and avoid accidents. Every drive, maneuver, and unexpected situation depends on the reliability of this system, which must always function correctly.

If brake pads or discs are not replaced in time, the braking performance deteriorates, and the stopping distance increases. In critical cases, a completely worn pad can damage the brake disc, cause the system to seize, or even lead to a total brake failure. Recognizing early signs of wear and performing timely maintenance are key to keeping both driver and passengers safe.

The purpose of this article is to explain how to determine how can I tell if my brake pads are worn, how to evaluate the overall condition of the braking system, and when replacement becomes necessary. Regular inspection ensures long-term reliability and helps prevent expensive repairs.

How long do brakes last?

The lifespan of a braking system is one of the most common questions among drivers. And it’s no surprise: brakes are directly responsible for your safety, so it’s important to understand when to expect wear and how to extend the life of the components. There is no universal mileage limit — it depends on driving style, operating conditions, part quality, and even the vehicle’s weight. However, there are average guidelines and official recommendations that help assess the system’s condition in advance.

Average lifespan of brake pads — 15,000–30,000 km

In most vehicles, front brake pads are designed to last 15,000–30,000 km, as the front axle carries most of the braking load. However, the actual lifespan can vary significantly:

- Aggressive driving (frequent hard braking, city traffic, rapid acceleration) can wear out the pads in 5,000–10,000 km.

- Calm highway driving can extend their lifespan — sometimes up to 40,000 km or more.

- On the rear axle, wear occurs much slower. This is especially true for drum brakes, which can last 100,000–150,000 km under normal conditions

To know when it’s time to replace your brake pads, check the thickness of the friction material (the recommended minimum is 5 mm) and pay attention to sounds — a metallic squeal or screech may indicate that the pads are worn down to a critical level.

Brake discs and drums — longer-lasting but still wear out

Brake discs and drums generally have a longer service life compared to brake pads, but they are far from “lifetime” components. In real-world driving conditions, they also wear out, overheat, and gradually lose efficiency.

Average service life of brake discs:

- Front brake discs: 60,000–80,000 km — they experience the highest load, especially during hard braking and city driving.

- Rear brake discs: 100,000–120,000 km — they wear more slowly due to reduced braking force on the rear axle.

There is a practical rule followed by most mechanics: brake discs are usually replaced after every two sets of worn-out brake pads.

This is because pads gradually grind down the disc surface, making it thinner or uneven over time. In addition to normal wear, discs are susceptible to several issues:

- overheating from frequent heavy braking can cause warping;

- vibration during braking due to a warped disc;

- corrosion caused by moisture and road chemicals;

- uneven wear when using low-quality brake pads;

If a disc becomes warped, resurfacing is sometimes possible, but only if the remaining thickness meets the manufacturer’s minimum specifications. When the disc is too thin or the damage is severe, replacement is the only safe option.

Signs your brakes need replacement

The braking system provides noticeable signals when parts start to wear out. Recognizing them early ensures safe driving.

1. Noises during braking

Squealing or high-pitched noises often indicate the pad’s wear sensor contacting the disc, signaling that the friction layer is nearly gone. This typically happens when the pad thickness reaches 2–4 mm. Metallic grinding is far more serious — it means the pad’s friction layer is completely worn out and the metal backing is scraping against the disc. This condition requires immediate attention.

2. Pedal feel and response

If the brake pedal feels unusually soft, spongy, or travels closer to the floor before engaging, it may signal air in the system, a hydraulic leak, or excessive pad wear. Vibrations felt through the pedal or steering wheel while braking usually mean bad brake discs, caused by warping or uneven wear after overheating.

3. Vehicle behavior

A car that pulls to one side while braking suggests uneven braking pressure or a sticking caliper. An increased stopping distance is another common indicator that braking power has been reduced.

4. Visual inspection

Look through the wheel spokes or remove the wheel to inspect pads and discs. Pads thinner than 3–4 mm need to be replaced soon. Cracks, grooves, or deep ridges on the discs are warning signs that they are approaching their service limit. At that point, consider when to replace brake discs to ensure consistent braking performance.

Step-by-step guide: checking brakes yourself

Regular self-checks of the braking system are simple but extremely important maintenance steps that help you spot wear early and avoid serious failures. Most basic tests can be performed without tools or technical expertise.

1. Listen for sounds during braking

While driving at a low speed, press the brake pedal several times—both gently and sharply.

- A squeak or high-pitched squeal often indicates that the wear indicator on the brake pad has activated. This is the first sign that it’s time to prepare for a replacement.

- A harsh metallic grinding sound is dangerous. It means the friction material on the pad has completely worn down, and the metal backing plate is rubbing directly against the brake disc. In this situation, you must stop using the vehicle immediately.

2. Check how the brake pedal behaves

With the engine switched off, press the brake pedal several times in a row.

- The pedal should become firm and resistant.

- If, while being held down, it slowly sinks toward the floor, this indicates a drop in hydraulic pressure—likely due to a brake fluid leak or a malfunctioning master cylinder.

3. Visually inspect the discs and pads

Even a quick look through the wheel spokes can reveal a lot. If possible, remove the wheel for a more accurate inspection.

- Brake pads: the remaining thickness of the friction material should be more than 3–4 mm. Anything less means it’s time to plan a replacement.

- Brake discs: check for deep grooves, cracks, or chips. A blue tint on the disc surface indicates overheating; such a disc may have lost structural strength and needs attention.

4. Pay attention to braking distance

If the car takes noticeably longer to stop or requires more pressure on the pedal, this is a clear sign of reduced braking efficiency. The cause may range from worn pads to hydraulic issues—all of which require a full inspection.

5. Check the brake fluid level

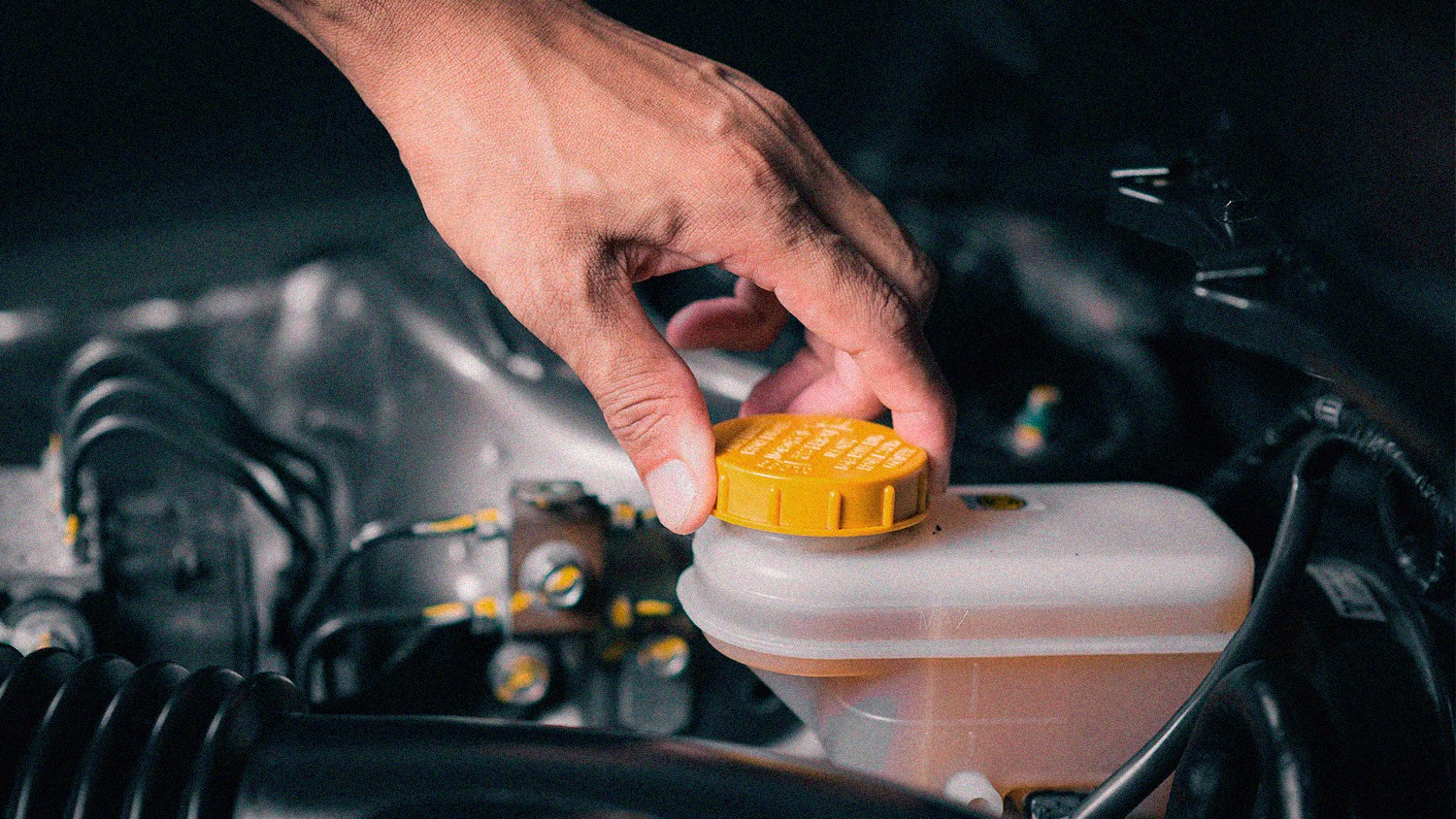

Open the hood and look at the brake fluid reservoir.

- The fluid level should be between the MIN and MAX marks.

- A gradual decrease in level without visible leaks often means the brake pads are wearing out, since the caliper piston extends further and occupies more fluid volume.

After completing these checks, you can form a basic understanding of your braking system’s condition. If you have even the slightest doubt—unusual noises, abnormal pedal behavior, or signs of disc damage—do not delay visiting a specialist. This is one of those cases where timely diagnostics directly affect safety.

Additional tests for better accuracy

If you’re uncertain about your results, two quick field tests can help confirm your findings.

- Parking test: with the engine running, press the brake several times. The pedal should remain consistently firm. If it feels different each time, there may be air or fluid issues.

- Road test: on a safe, open road, decelerate smoothly from 60–80 km/h. If you feel vibration or steering pull, the discs are likely warped or uneven.

When to visit a mechanic

While self-diagnosis is helpful, a professional mechanic can make precise measurements and detect hidden problems. Seek help if:

- You hear grinding or scraping. This means metal-on-metal contact between the pad and disc, leading to expensive rotor damage.

- The pedal sinks or feels too soft. Possible causes include hydraulic leaks or a faulty master cylinder.

- You are unsure about the system’s condition. Professionals use tools to measure pad thickness, disc runout, and test fluid pressure accurately.

Routine inspections every 10,000–15,000 km, or at least once per year, are highly recommended. This helps determine how often are brake rotors replaced based on your driving style and environment.

How to make your brakes last longer

Proper habits can significantly extend the lifespan of your brakes:

- Avoid harsh braking. Smooth, gradual stops prevent overheating.

- Use engine braking. Downshifting on descents reduces load on the braking system.

- Avoid unnecessary weight. Driving with heavy cargo increases braking force and heat.

- Monitor brake fluid. Replace it every 2–3 years since it absorbs moisture, which lowers boiling point and can cause vapor lock during hard braking.

Conclusion

Learning how can I tell if my brake pads are worn is a vital skill for every driver. The braking system is the cornerstone of vehicle safety and must always be in perfect condition. Simple tests — listening for noises, feeling pedal feedback, and inspecting components — can reveal problems before they become dangerous.

It’s always safer to replace brake pads or discs slightly earlier than too late. The cost of preventive maintenance is minimal compared to the price of replacing damaged rotors or risking an accident. Stay attentive, and your braking system will serve reliably for years to come.